Most of our clients look to Crown Conveyors to design and engineer a tailored solution to resolve a new production challenge. Our approach is to first get a comprehensive understanding of your objectives and then develop the solution. This process will usually encompass:

Site Survey

During our site survey we will assess all client requirements and make suggestions to the various options to achieve the clients aims and production targets.

Design

Designs are produced with 2D AutoCAD & 3D AutoDESK Fusion 360, drawing formats provided can be AutoCAD, IGES, STEP, SAT & PDF. We also offer 3D Printed prototypes for intricate applications.

Budget Focus

We closely monitor all stages of the projects to ensure they are delivered on budget to the customers requirements.

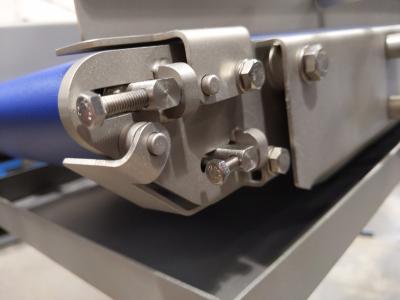

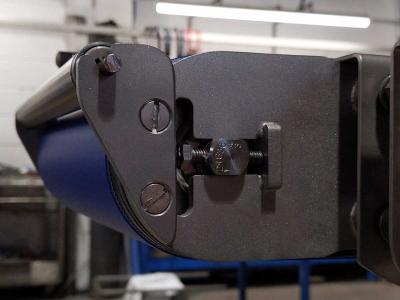

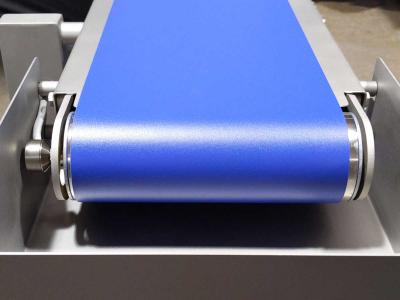

Customise

We can customise and alter the design of your conveying production line as necessary, this can be completed on any new or existing equipment.

Installation

Our team of fully qualified and competent engineers will install and test all equipment with minimum disturbance to your production and workflow.

After-sales

After installation whether you require spare parts or perhaps require some maintenance on your existing equipment or a service plan, our engineers will assist in keeping your line running.

3D Printing

3D printing enables us to quickly construct a three dimensional object from a computer created design. We print Polymer to food safe standard which can be used in concept, one-offs, prototypes or end use products. Everything we print can also be integrated into your existing set-up or infrastructure.

Every project is fully supported by full CE documentation and spares list. We also provide a 'peace of mind' service that guarantees a fast response to breakdowns – of any manufacturer's products. We offer extensive stocks of standard parts and fast access to non-standard items and a competitive hourly rate.